Five and Seven-Layer Co-Extrusion High Speed Blown Film Line

Categories : Co-Extrusion Blown Film Machines

K.S. became a worldwide company; have achieved ISO 9002 certificate's requirements. K.S. machinery conforms to CE standard. Moreover, every machine must pass K.S. strict and careful quality control system, and pass test running before shipping out to the customer.

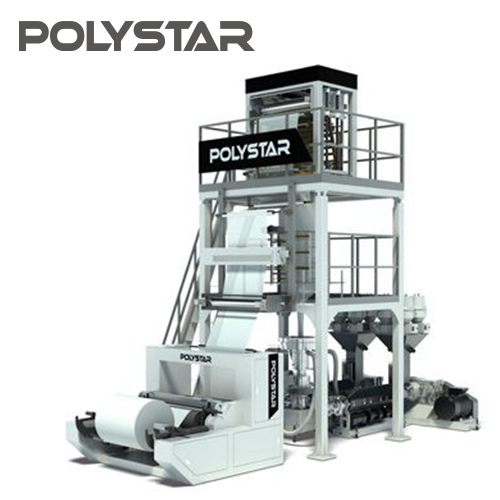

ABA Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

● ABA 3 Layer Co-extrusion ● Film Width from 500~1500mm ● Extruder Dia: 40mm,45mm, 55mm, 65mm ● Material: HDPE,LDPE, LLDPE,CaCO3, Additives ● Output: 45~150 kgs/hr

OSCILLATING TOWER ABC THREE-LAYER BLOWN FILM MACHINE

Categories : Blown Film Extruders

The ABC three-layer co-extrusion machine is your ideal choice for producing high-end plastic products, such as shrink films, agricultural mulches, electrical insulation films, packaging films, medical packaging films, stretch hood films. The raw material formula for each layer can be customized respectively according to your requirements. The oscillating haul-off unit provides excellent film gauge randomization, ensuring the production of high-quality and wrinkle-free films. The oscillating haul-off unit is also rather durable, and its equipment lifespan is much longer than the rotary die. Suitable for producing three-layer films for specific functions Recycled materials or CaCO3 is applicable to the middle layer in order to save material costs Die and air-ring specially designed for producing high-quality three-layer films 360° Oscillating Haul-off unit improves film thickness uniformity EPC (Edge Position Controller) Full customization according to your specific requirements

TWO-COLOR CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Equipped with 2 extruders, A/B type blown film machine is able to produce two layer/two colours film. This machine can produce two-color-striped films. Final products have obvious streak of two separate colors. Upgrade die and air ring to produce HDPE and LDPE 2 layer film.

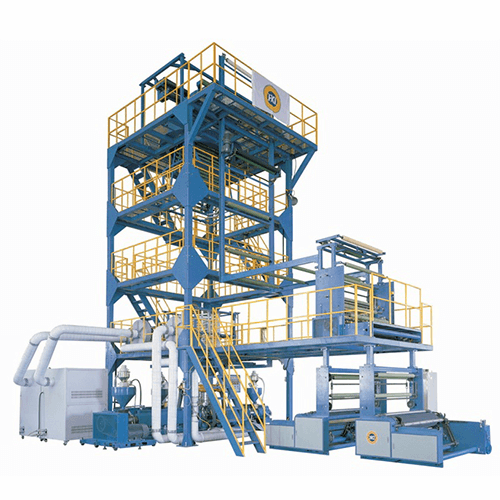

A/B/C BFS Series Co-Extrusion Blown Film Line

Categories : Blown Film Extruders

FKI offers one of the most advanced and adaptable blown film lines for various applications, such as shopping bags, vest bags, garbage bags, agricultural film, construction film, packaging film and lamination film, etc. The workable materials that can be used are such as LDPE , LLDPE, MLLDPE, and HDPE. The film production range is from 200mmto 7 meters in tubular width, and the production output rate is from40kg/hr to800kg/hr. Based on 30 years of experience, FKI is capable of offering blown film lines with reliability and versatility to meet different requirements from mono layer, double color, double layer, and three layer to four color designs.

A/B/A BFT Series Co-Extrusion Blown Film Line- Rotary Die Head

Categories : Co-Extrusion Blown Film Machines

A/B/A BFT Series Co-Extrusion Blown Film Line- Rotary Die Head

A/B/A BFT Series Co-Extrusion Blown Film Line- Oscillating Tower Type

Categories : Co-Extrusion Blown Film Machines

Tubular lay flat width:From 40mm to 7 meter. -MONO LAYER, TWO LAYER, THREE LAYER & FIVE LAYER -SINGLE COLOR, DOUBLE COLOR, UP TO 4 COLOR.

AB & ABA CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Equipped with 2 extruders, A/B or A/B/A type blown film machine is able to produce two-layer film. Co-extrusion able to choose from AB to ABA, ideally for 2 layer film with different colour or apply CaCO3 in middle layer for cost saving, etc. Perfectly suitable to agriculture film, shipping bags, shrink film, consumer packaging and many others.